The Prospect of Digital Power Supplies – Combination of DRP/DBR-3200 Series and CMU Controllers for System Power

Viewers : 184

By Dr. Leon Ku/Research and Development Dept.

1. Digitalized PSU(1) The advantages of digitalized PSU

The conventional power supply is based on analogous control which has advantages of low cost, simple circuity design and fast response. However, there are some disadvantages of analog PSUs, such as limited application, specific function, unable to integrate complex power system by using simple interface and difficult to fine-tune the compensation of control loop. Digitalized power supply has a programmable power management interface to set up different operating modes and control parameters via software to meet the needs from different applications. Table 1 below shows the advantages of digitalized PSU.

Table 1: The comparisons between digitalized PSU and analog PSU

| Digitalized PSU | Analog PSU | |

| Efficiency | High | Low |

| Power density | High | Low |

| Product size | Small | Big |

| Component count | Less | More |

| Reliability | Excellent | Moderate |

| Human-machine interface | Yes | N/A |

| Control/ monitoring | Easy | Difficult |

(2) DRP/DBR-3200 series digital power supplies

DRP/DBR-3200 series products are high efficiency power supplies which have 1U low profile with high power density up to 37W/inch3, built-in PMBus and CANBus (optional) protocols and parallelable. DRP/DBR-3200

series products provide vast design flexibility, multi built-in functions including three stage programmable charging curves (DBR-3200), programmable output (PV & PC), active current sharing, remote on/off control,

auxiliary power, hot plug, and etc. Fig. 1 shows the DRP-3200 power supply module and Fig. 2 shows the power system of DHP-1U power shelf.

Table 2: list of products

| Product | Description | Note |

| DRP-3200 | Rack power | Four PSUs in one power shelf |

| DBR-3200 | Rack charger | Four PSUs in one power shelf |

| DHP-12K1UT DHB-12K1UT |

4 DRP-3200 PSUs in one power shelf 4 DBR-3200 PSUs in one power shelf |

Maximum ten rack shelves can be connected in parallel operation. Total power is up to 128kW. |

|

|

| Fig. 1 DRP-3200 power module | Fig. 2 DHP-12K1UT power shelf power system |

2. System power

(1) CMU controller

RKP-CMU1 controller is a fully digitalized control/monitor controller with power management human-machine interface, remote control/monitoring via wired or wireless network and fast reading system power data. The major functions and features of RKP-CMU1 are 1U low profile, 19” power shelf installation, programmable digital control and system monitoring, equipped with USB, RS-232 or Ethernet interfaces to connect PC/NB locally, recording the time and date of the alarm/abnormal events, and etc. Fig. 3 shows the RKP-CMU1 controller and Fig. 4 shows the 19” 1U low profile RKP-1U-CMU1 power shelf.

|

|

| Fig. 3 RKP-CMU1 controller | Fig. 4 19” 1U low profile RKP-1U-CMU1 power shelf |

(2) System power architecture

System power is the best choice for high power applications due to the following advantages, such as integrated power control/monitoring and unified power management, greatly improving management efficiency, high energy efficiency, reducing the complexity of installation, wiring and maintenance, and reducing operating costs significantly.

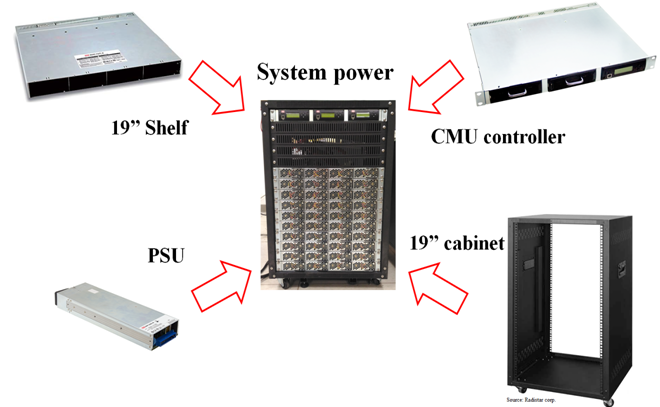

System power contains the following software and hardware components,

- Hardware includes power supply modules, 19” power shelf, RKP-CMU1 power shelf and 19” rackmount cabinet as shown in Fig. 5 below.

- Software (RKP-CMU1 controller) comprises of power management human-machine interface, communication interfaces (I2C, RS-485, RS-232) and protocols (CANBus, Modbus, PMBus), Networks (LAN, WAN, CAN), and etc.

Fig. 5 The components of system power architecture

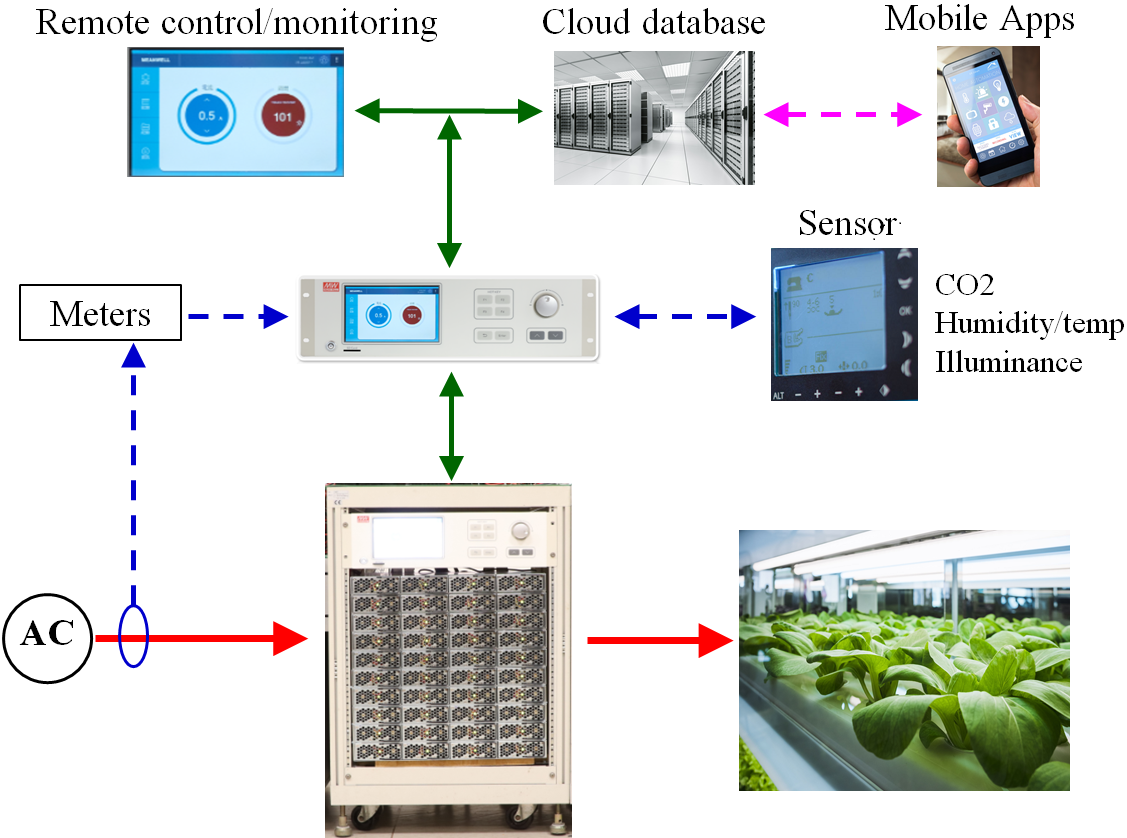

In order to meet the applications of power control/monitoring in different industries, MEAN WELL is developing a new generation of system power controller CMU2 (expected to be launched in 2019 Q4) as shown in Fig. 6 below, which has more functions, such as optimizing human-machine interface by using touch panel, diversified data formats (ex. chart analysis; report analysis, and etc.), network technologies (Web; TCP/IP; cloud), increased IoT interface function scalability, integrated control over various types of power products. Fig.7 shows CMU2 in system power.

|

|

| Fig. 6 CMU2 (Rack version) | Fig. 7 CMU2 in system power |

- The applications of the system power

Fig.8 The system power application – plant factory